During the Hunter Industries learning tour Feb. 4, Michael Kuhn (left) and Andy Staples tag-team a presentation on irrigation from the different and sometimes conflicting viewpoints of irrigation consultant (Kuhn) and architect. Photos by Andrew Hartsock

Given the importance of water to golf course maintenance and the importance of irrigation in the management of that precious resource, perhaps it’s no surprise that close to 60 superintendents opted to dedicate close to 10 hours to learning about both on Monday at the Hunter Industries Irrigation Learning Tour, part of the 2019 Golf Industry Show in San Diego.

Superintendents from nearly half the states and a handful of foreign countries, from Guatemala to Taiwan, spent the bulk of their daylight hours Monday on the soggy grounds of Hunter’s U.S. headquarters in San Marcos, Calif., immersed in all aspects of irrigation, from source — specifically, maintaining water quality in on-site ponds and lakes — to sprinkler and points between.

“Irrigation,” proclaimed irrigation consultant Michael Kuhn, president of Michael Kuhn & Associates, “is the No. 1 tool you use, and if anyone doubts that, I’d be glad to talk to them.”

For the record, nobody disputed Kuhn’s assertion, and the day buttressed that point with a soup-to-nuts breakdown of how to assess a course’s irrigation system and keep it in prime working order.

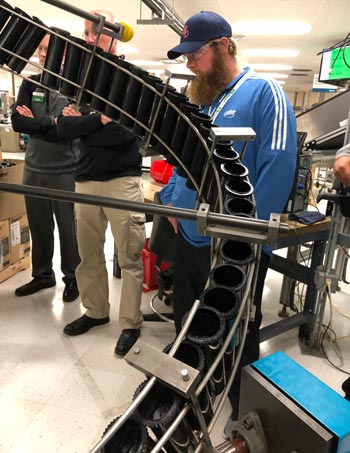

Right: Superintendents get an up-close look at the Hunter Industries production facility in San Marcos, Calif.

Take, for instance, the talk by Charles Barebo of Otterbine-Barebo Inc., who stressed the importance of maintaining a healthy water supply, as poor quality water makes for poor irrigation. Barebo said EPA research has shown that 44 percent of all lakes rank fair or poor in water quality, and that the number rises to 60 percent for man-made lakes.

John Murtaugh of Motor Controls Inc. presented on pump maintenance and tips and tricks for keeping a pump station in top working order. Irrigation consultant Les Hill gave a compelling talk on the history of irrigation — did you know the use of copper pipes to transport water can be traced back to 4000 B.C.? — and also discussed the difference between an irrigation assessment and an irrigation audit. Using the analogy of a car tuneup, he said an audit can get a car running more efficiently, while an audit will do the same, plus determine the transmission is going out and the tires are flat.

Superintendents were also treated to a joint session by Kuhn and architect Andy Staples (Staples Golf Design) — they recounted their often conflicting approaches to irrigation practice, though they share common ground on its purpose — as well as Greg Baer (Baer Design Group). Those presentations dovetailed nicely around the importance of distribution uniformity, or DU, which is the measure of how uniformly water is applied to an area being irrigated.

Kuhn contends that DU is the starting point for designing a course’s irrigation system, and that control — that is, the sprinklers or nozzles — must be secondary. “Treat your property as one monolithic piece of turf,” he advised. “Once you get that right, then you can add more control.”

Testing sprinkler output in the Hunter Industries wet room.

Baer followed Kuhn’s talk with a discussion of measuring DU. According to Baer, a DU of 85 or higher is “excellent,” 80 percent is “very good,” 75 percent is “good,” 70 percent is “fair,” and 65 percent or lower is poor. If a superintendent finds it impossible to get a course’s system over the 65 or 70 percent mark, the time may have come to consider improvements to the system, Baer said.

Baer highlighted financial reasons that would make such upgrades worthwhile. He provided an East Coast example where a system that improves from a DU of 60 to 70 percent would save close to 4 million gallons of water in a year, a financial savings of $19,000 plus a significant decrease in pump hours. The West Coast example for the same hike from 60 to 70 percent would save close to 7.6 million gallons of water, worth $35,000 and even more pump hours.

The learning tour also included a trip through Hunter’s production facility.

Andrew Hartsock is GCM’s managing editor.