Mariana Butte Golf Course, an 18-hole facility that opened in 1992, is within an hour’s drive of Denver and is one of three golf courses under the management of the city of Loveland, Colo. Photos courtesy of Steve Southard

Far too often, irrigation problems are simply masked with wetting agents and additional hand watering. In late summer, though, superintendents have the opportunity to assess and troubleshoot their irrigation systems by performing a turf stress test, which will uncover areas of turf that aren’t receiving proper irrigation — some of which may not be noticeable otherwise. A stress test will expose all the weaknesses in your irrigation system, and although this will present temporary discomfort, identifying, understanding and correcting your irrigation issues will allow you to be in greater control and face fewer difficulties in the long run.

The city of Loveland, Colo., operates a trio of golf courses — Mariana Butte, Cattail Creek and The Olde Course — and as the city’s golf operations manager, I split my time among the three. The ages of the courses differ, as do the ages and capabilities of their irrigation systems. Mariana Butte is a resort-style golf course in the foothills of the Rocky Mountains, and it has a 25-year-old Toro irrigation system. Cattail Creek is a par-3 course with a 26-year-old Rain Bird control system and Toro irrigation heads. The Olde Course is a 54-year-old course with a 10-year-old Rain Bird irrigation system. Our Mountain West, high desert region is known for high evapotranspiration (ET) in summertime, minimal rainfall, and water quality challenges.

During summers, three or four crew members at each of the courses were assigned to daily hand-watering duties to respond to hot spots and stressed turf, and they would return to work on Saturday and Sunday afternoons to ensure the courses were surviving the midsummer heat.

I developed the idea of a stress test as a way to pinpoint areas with poor distribution uniformity (DU) — an alternative to continuing to purchase gallons of wetting agent and having employees spend more hours with hoses in hand. In summer 2015, I instructed the maintenance staffs at all three courses to put away the products, park the hand-watering carts and reduce their deficit irrigation programming, and to turn their focus instead to improving DU as a means of permanently eliminating localized dry spot, decreasing daily hand watering and relieving midsummer stress.

First things first

Do your research. Know the design of your irrigation system, and measure DU at the outset, before you attempt to implement any improvements. By closely observing the irrigation patterns at our three courses pre-stress test, the staffs shifted from a mentality of “It has always been that way” to “Why is it that way?”

Test wisely. Not only is DU testing necessary, but who performs the testing is also important. Crew members often don’t have the formal training or continuing education opportunities that superintendents do. A sensible strategy is to have the irrigation staff perform the DU testing under the superintendent’s supervision and direction.

Shape of sprinkler head spacing greatly affects DU. One hundred percent distribution uniformity is not possible — all irrigation systems will have weakly and heavily watered areas. Uniformity can exceed 90 percent with triangular spacing of irrigation heads, however, which is more efficient than square spacing. In a wet and humid area, square spacing may be adequate, but here in the arid high desert, triangular placement always produces more even water distribution. On large putting greens, the irrigation design may have an unusual spacing of heads, which may significantly hurt DU. Be especially leery of pentagon-shaped head spacing for large round greens. Such an arrangement typically leads to a green that’s too wet in the middle and dry along the outside.

Elevation matters. Along with head spacing, pressure and nozzle selection, the elevation of your golf course will determine sprinkler heads’ effective throw distance. Air density at higher elevations results in a noticeably different rain curtain than what’s published in manufacturers’ brochures. Superintendents and irrigation designers shouldn’t blindly trust performance data that was collected on an indoor test site located near sea level (unless your course is located indoors and at sea level). The nozzle performance tables can get you close to an accurate estimation of appropriate nozzle selection and head spacing, but superintendents should always trial nozzle performance at their site using accepted DU test methods. Loveland sits at 5,000 feet above sea level, and the throw from our irrigation heads is 7 to 9 percent farther than that of the same irrigation heads operating at the same pressure but located at sea level.

If sprinkler head spacing is consistent course-wide, the water distribution pattern will be consistent. If a course has an irrigation uniformity problem and head spacing is relatively consistent, the irrigation pattern will be repeated throughout the course. This can often be seen more easily via satellite imagery taken in the heat of summer or during a drought period. If the pattern is consistent, diagnosing what’s wrong will be easier.

Time to test

To perform the stress tests at our three courses last summer, each course’s irrigation system was programmed to deficit-irrigate at 50 percent of the previous day’s evapotranspiration (ET), instead of the typical 60 to 65 percent of the previous day’s ET. Staff applied supplemental water by hand only two days per week (Tuesday and Friday). Within a few days of starting the tests, the turf became stressed, and a mosaic of irrigation patterns appeared. Now our detective work could begin.

On the fairways at two of the courses (Mariana Butte and The Olde Course), we discovered that the area around each sprinkler head stayed wet while the space between the heads began to go dormant. The findings on the third course (Cattail Creek) were the opposite — the areas around each head became bone-dry, but those between the heads remained healthy. Staff noticed the same patterns on the greens, which was something that had gone almost entirely undetected back when routine application of wetting agents and daily hand watering were the norm. About a week after initiating the tests, each course had a turf palette that resembled a checkerboard, and we were ready to dive into DU testing.

Measuring DU

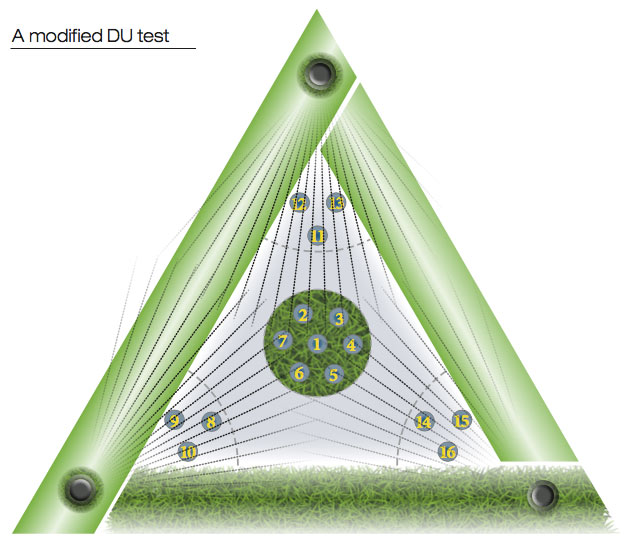

Standard 40-catch-can DU tests can take a long time to complete, and we realized that with our triangular head spacing, the amount of water in the middle of the triangle should be nearly equal to the amount of water near each head. So, we used only the center seven catch cans and the nine external catch cans of the typical 40-catch-can DU protocol. I would rather have staff address 20 areas at 95 percent accuracy than 10 areas at 98 percent accuracy. Using this modified method, a DU test result of 95 percent or higher will provide uniform and excellent playing conditions.

By gauging the water gathered by just 16 catch cans rather than the usual 40, staff at the city of Loveland’s three golf courses were able to slash the time spent testing distribution uniformity for their triangular-spaced sprinkler heads while still gleaning an authentic picture of their irrigation situation. Graphic by Roger Billings

The first DU test percentages ranged from the high 60s to the low 70s at Mariana Butte and Cattail Creek. The newer irrigation system at The Olde Course was slightly better, with DU percentages in the 70s. Although these tests sound equally terrible, the field observations established a dramatic difference: The soil moisture at Mariana Butte and The Olde Course was higher around the heads, whereas the soil at Cattail Creek was wet in the space between heads.

One related note: Although the catch-can method is the best method to calculate DU, soil moisture meters are also a good tool for measuring water accumulation in soil. We use the FieldScout TDR 300 to identify areas that might be getting too much water, as well as to determine when the turf will begin to wilt. Any 20-handicapper can tell when turf is wilting, but recognizing a slow accumulation of water caused by uneven irrigation distribution is often impossible. Superintendents can use soil moisture meters to identify heavy irrigation areas, and then have the irrigation staff verify the overwatering via the catch-can method.

The fastest and easiest remedy for our flawed irrigation patterns was to make sure we were using the correct nozzles at each course. The original nozzles at Mariana Butte had a throw distance between 85 and 90 feet despite head spacing of 72 feet — a definite overthrow. The Olde Course had a similar overshoot of about 10 feet on all fairway heads, while at Cattail Creek, particularly small nozzles had a throw of 55 feet but were spaced at 65 feet. After testing many nozzle types (both original manufacturer and aftermarket), we replaced all the nozzles on all three courses. The cost of the nozzle upgrade was small, and the improvement was dramatic.

Lessons learned

Long-held assumptions may not be accurate. For years, Cattail Creek staff thought the course’s unhealthy turf was the result of “salty” irrigation water. In the 1990s, the course had a sulfur injector installed in the pump station, and in 2004, an inline magnetic water-conditioning device was added to the mainline just downstream of the clay valve. Former crew members spent countless hours aerating the dead sections in the fairways and roughs, which appeared in the same places every summer. After our stress test and swapping out the nozzles on all the irrigation heads throughout the 34 acres of turf, we began to see a significant improvement in turf health. The sulfur injector and inline water conditioner were removed, aerification in the fairways and rough ceased, and midday watering was suspended.

The takeaway: Although the Cattail Creek water supply is slightly “salty,” the even application of water gave us a healthy stand of turf. The quality of the water wasn’t perfect, but neither was it horrible, and evenly applying the water trumped minor salinity problems.

The stress test at Mariana Butte revealed oversaturation around sprinkler heads (designated with blue flags) while the space between the heads was dry and wilted.

Technology can help you communicate. Soil moisture meters, computer-generated DU simulation, and satellite photography can aid in the process of improving irrigation efficiency. We used the SPACE Pro software from Fresno State University’s Center for Irrigation Technology to visually explain our irrigation problems to a citizen golf advisory board whose members had limited knowledge of or experience with irrigation design. The software translates DU data from lab tests into images to show the areas that will receive heavy or light irrigation depending on head spacing and nozzle selection.

Run times on some control systems are truncated. Two of the irrigation systems were controlled using ET, and the third irrigation system was controlled based on run times. After much observation, staff identified that the cycle and soak option on the third system truncated irrigation run times by a multiple of the number of cycle times. For example, an area with three cycles only had the option of running for three, six, nine, 12 or 15 minutes. In the high desert, this limitation can be troublesome. If an irrigation station is programmed for, say, 10 minutes, and the global adjust is 80 percent, you might expect the run time to be eight minutes. When three cycles are used, the run time is truncated to six minutes, the closest interval divisible by three that’s less than the run time calculation. The outcome is 25 percent less water applied than the intended eight-minute run time.

Program water applications to ET, even when irrigation programming is based on run time. With newer irrigation systems, this is simple, as most superintendents know the percentage of deficit irrigation required to maintain healthy turf. With our system, consistently watering at 60 percent of ET will eventually deplete the available water in the turf and lead to stress, while consistently watering at 70 percent of ET will produce succulent turf with wet, soft playing conditions. The irrigation programmer thus toggles between 60 percent and 70 percent of ET, based on the playing conditions in the field.

If you can’t program to ET and are using run time-based programming, convert daily ET rates into a percentage of that original program run time. This step is absolutely necessary, as different employees may have different assumptions about how much water is applied when the program is set to 100 percent. For instance, a breezy summer day in early July with a temperature of 95 degrees Fahrenheit and 15 percent humidity might produce an ET of 0.28 to 0.30 (which would need a global run time of 110 percent). A 95-degree day with 15 percent humidity in late August, however, may only result in an ET of 0.23 (which would need a global run time of 90 percent). A program setting of 100 percent is not logical for both days. Convert the daily ET rate to the correct global run time to allow for an irrigation event that matches the daily ET rate.

Stressed to impress

Stress tests have allowed us to eliminate nearly 100 percent of recurring localized dry spot on the three courses, which is a big claim here in the high desert. Hand watering is now done only on Tuesdays and Fridays, and it’s implemented only in areas that receive slightly less moisture than the surrounding turf. Remember: One hundred percent distribution uniformity is not achievable, so there will always be a need for supplemental hand watering during extended dry periods.

Mariana Butte Golf Course is nestled in the foothills of the Rocky Mountains in the western part of Loveland, Colo.

A great irrigation goal for maintenance staffs is to eliminate all watering after 9 a.m. Midday watering is inefficient, as much of the water that’s applied can be lost to evaporation. The practice can also change playing conditions from one group to the next, and it increases electricity usage and shortens the life of the pump station. Do your best to irrigate right at night, and you’ll save money and have less work during the day.

While wetting agents and hand watering are normal, acceptable medicines for irrigation inefficiencies, consider documenting the obvious problems and troubleshooting the root causes of those problems with the help of a stress test. You’ll likely find that most of the improvements are relatively easy to implement, such as changing nozzles or refining sprinkler head spacing. The benefits of such self-evaluation are long-lasting and numerous: less need for hand watering, less dependency on wetting agents, fewer wet areas, more uniform playing conditions, less energy use, fewer employee visits to the golf course during high-stress periods, and, of course, an overall reduction in expenses.

Steve Southard, CGCS, is the golf operations manager for the city of Loveland, Colo., where he has worked since 2006. A 12-year member of GCSAA, Steve is also a Certified Park and Recreation Executive. He and his wife, Marcia, have three children, Duncan, Alex and Carly.