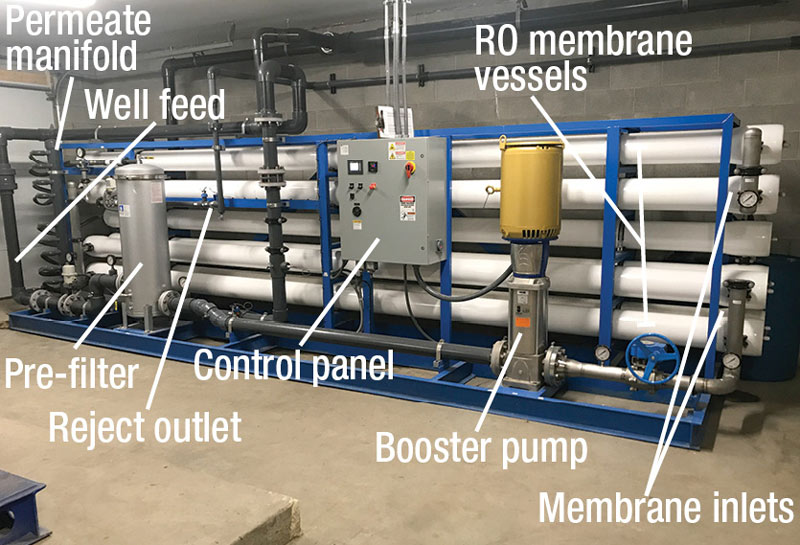

Park Ridge (Ill.) Country Club invested in a reverse osmosis water treatment system in 2017 to address the high level of contaminants in available well water, allowing the facility to avoid paying the high price for city water. This is the system in its winterized state. Photos by Joel Purpur

Do you irrigate your golf course with less-than-desirable water, which in turn contaminates your soils and affects the health of your turf? Odds are, at some point in your career, you will deal with less-than-ideal water. A reverse osmosis water treatment plant could improve the situation for you.

Many golf course managers are forced to use water that is considered poor in quality, whether it is effluent or from other sources that contain high levels of contaminants or register high levels of total dissolved solids (TDS), which happened to be our main problem here at Park Ridge (Ill.) Country Club. Salesmen are not shy about trying to sell products or methods to improve water quality. Depending on the type or the severity of a given water problem, a chemical approach could work for some situations, but we were not sold on the other methods we investigated, mainly because of the salinity of our water.

In many areas of the country, deep wells are often a good water source. The property at Park Ridge Country Club has a fairly deep well (drilled to 1,300 feet), but the bedrock in the area was fractured from a large meteorite that crashed in the area “with the force of thousands of hydrogen bombs” millions of years ago (look up the “Des Plaines Disturbance” if you are curious or have insomnia). With fractured rock as deep as a mile in the area, the aquifers are more or less all connected and cross-contaminated. Therefore, spending money in hopes that a well at a different level would yield better water was not a recommended or guaranteed option.

Years ago on the golf course, plant health was regularly affected by the well water, which had elevated TDS levels (1550 ppm) as well as higher-than-desired levels of bicarbonates, chlorides and sulfur. Consequently, the club switched water sources and purchased Lake Michigan water from the city for over two decades. Lake Michigan water is of excellent quality, but it certainly comes with a high price tag. During dry years, the club spent as much as $140,000 a year on water (which is high in the Midwest for a course watering only greens, tees, fairways and surrounds), and that was before the course had wall-to-wall sprinklers throughout the property.

In addition to the high cost, daily limits and increasing talk of additional restrictions during drought periods were also concerns. With water costs predicted to double in the near future, we realized we might recoup our costs in a few years and help alleviate some of the restriction concerns if some type of water treatment system would work for us.

Reverse osmosis to the rescue

Reverse osmosis (RO) systems have been around for quite some time, and many people use them in their homes. Commercial RO systems that produce the volumes of water that golf courses need have also been around for a while, particularly in coastal areas where potable water is sourced from the ocean.

Park Ridge Country Club’s reverse osmosis water treatment system being lowered into place into its partially constructed building during installation in 2017.

In simple terms, the systems take ocean water and run it through a series of “filters,” keeping the clean water and dumping the salty part back into the ocean. That sounds simple enough. So, how does an RO system work, and what does the “reverse” component mean?

BlueTech, an international manufacturer and distributor of water purification systems, offers these definitions:

Osmosis is a natural process that balances two bodies of water separated by a semipermeable membrane. Water flows through the semipermeable membrane from the less concentrated solute (fewer contaminants) to the highly concentrated (more contaminants) to restore equilibrium between the two sides. A semipermeable membrane has small holes that trap contaminants but allow water to flow through.

Reverse osmosis occurs when pressure is applied to the solute that has a high concentration of contaminants. For example, when pressure is applied to a volume of salt water, the salt is left behind when the water passes to the other side of the membrane. Now, the salt water is drinkable. The fresh water produced is called the permeate. The concentrate left over is the waste, or brine.

What to do with the brine has long been a question for those who want to use RO systems in non-coastal areas. As treatment systems have gotten better through advancing technology, the process has become more efficient, and the amount of reject brine has decreased (only 15% with our model), meaning there is less reject water to dispose of. Depending on the contents of the water being cleaned, the brine will most likely not generate enough of a concentration of toxic substances to be classified as a type of hazardous waste. That is important if you are seeking a permit to dispose of the reject water into the sewer system, which was our intent.

Plumbing and production

The company we purchased the equipment from, MCI, employs a water expert. He took our raw water report and produced a breakdown of the projected contents of both the permeate and the reject water, which was needed for the permitting process.

The permeate water the system produces is extremely clean — so clean that it can be a bit corrosive. We needed to have certain parts of our pumps and pump station protected from corrosion by using stainless steel components or coatings on the contact parts prior to using the RO water. We were fortunate to be installing a completely new pump house, RO system and pump station together, so everything was coordinated and compatible.

Conductivity monitors were installed in the wet well for constant monitoring and safety. There is a direct connection between the amount of solids (usually mineral salts) dissolved in the water and its conductivity: The more salts dissolved in water, the higher the value of electrical conductivity. As a precaution, the plumbing plan made provisions so that the well water could bypass the RO system if ever there were a problem. Also, if the conductivity of the pond water gets too low (too corrosive for the health of the soil), we can run the untreated well water directly into the reservoir pond to “dirty up” the pond water a bit and raise the conductivity level in the reservoir fairly quickly.

A worker installs a membrane into a reverse osmosis membrane vessel. Replacing all the membranes is expected to cost $40,000 to $45,000, but the membranes should last at least five to 10 years.

The primary components of the reverse osmosis system at Park Ridge Country Club, an 18-hole private course.

Reverse osmosis systems operate best if they run 24/7. Water must run through the membranes regularly. Even if we are not irrigating, we typically run our system at least every other day for an hour or two to prevent the membranes from scaling up or fouling. They cannot sit idle or there is risk of damaging the membranes, which are very expensive. Each time the system is turned on, it automatically back-flushes for several minutes before pushing water through the membranes to keep them free of obstructions.

Sizing the system’s production capacity was based on what we typically use for irrigation with an “average” watering cycle, which in our case is about 350,000 gallons per day.

Each RO system is composed of a series of vessels (tubes), which each contain membranes (filters) to scrub the water. With our system, each of the nine vessels contains six membranes, for a total of 54 membranes. Each vessel has a maximum capacity of water that can filter through it, so depending on the maximum amount of product water desired in a given day, the higher the desired output, the greater number of vessels needed in the arrangement.

A manifold collects the product water from the center of each of the nine vessels and sends it through the product-discharge pipe, which goes directly into the reservoir pond.

Right: A look at the reverse osmosis system’s product-discharge hoses (gray), which feed into the product manifold, which discharges into the reservoir.

If we had a larger pond with more storage potential, we might have sized it a bit larger, but we knew that we had the option of supplementing the reservoir pond with the city water source if the RO couldn’t meet the demands during abnormally prolonged dry periods. The brine that does not make it through the membranes is discharged from the outside part of the vessels and exits the system through a discharge pipe.

Pond-level sensors were set in the wet well to start the RO system automatically after a small drop in the pond level. There is also an automatic shut-off level and a manual option if we want to pre-charge the pond level in preparation for a high-demand irrigation cycle.

During a couple of extended dry periods, the system ran 24/7 for weeks straight, which is actually best for the system. In the two years of operation thus far, we have only used city water to supplement the RO a few days when the forecasted rain never occurred and we had to play catch-up with the rough to keep it from going dormant.

We monitor several pressure gauges daily, and readouts on the system are observed and recorded, mainly looking for changes in pressures or levels. These might signal the need for a pretreatment filter change, a problem with the membranes, the need for minor adjustments to the permeate or reject flow amounts, or other possible malfunctions.

Costs of a reverse osmosis system

So, what was the initial investment, and what are the main operating costs?

Here is the breakdown:

- In 2017, our 350,000-gallons-per-day unit cost about $235,000, which included installation.

- A pretreatment antiscalant chemical is constantly pumped in small amounts into the system during operation to keep the membranes clean and unclogged. A 55-gallon drum of antiscalant runs about $1,600. If we operate the RO system an average of 12 hours per day, every day, 55 gallons of antiscalant will last almost six months. We used a total of about 70 gallons of antiscalant per year each of the last two years.

- The membranes are expected to last at least five to 10 years. They are a bit costly — $40,000 to $45,000 to change them all for a system of this size — but the average yearly cost is still low compared with the cost of purchasing water.

- Pretreatment filters run about $600 per year if you have fairly clean water going into the system. If your source has a high enough level of silt particles, you will need to have an additional pre-filter, as silt will clog the membranes.

- The 350,000-gallons-per-day system is run by a 30-horsepower motor, so depending on what you are paying for power, you can figure on adding that electrical cost.

- If your supply is from a well that has not previously been part of your budget, the cost to run that pump needs to be added as well.

Right: The reverse osmosis system’s clean-in-place (CIP) unit, which gets installed for winterization.

- The first couple of years, we observed the experts from the company winterize the system, and you will need to add that cost.

- We feel comfortable doing the winterization in-house next year, but we will still hire the expert for the spring start-up to make sure everything is dialed in properly out of the gate, which is another cost to figure in.

- Adding it all up, we figure to produce water at about 15% to 20% of what we were previously paying for water (depending on the life of the membranes).

Winterizing the unit is a bit different from what we are used to doing with irrigation systems. A separate and somewhat portable recirculation pump system and a large nylon tank (which comes with the system) are hooked up to the RO plumbing like an artificial heart. That setup circulates a chemical preservative solution (which depletes all the oxygen in the membranes) throughout the membrane chambers repeatedly for about 20 minutes so that nothing can grow biologically in the membranes during the idle time after the system has been put to bed for winter. Compressed air is not needed; everything is gravity-drained.

Working with the contractors Leibold Irrigation Inc. and MCI was gratifying. They had a wealth of knowledge and worked with us to make sure everything went like clockwork from installation to operation.

The club is positive about the investment and is already seeing the benefits of the RO system. Most notably, it is happy to see a very inactive city water meter.

Joel Purpur, CGCS, has been the superintendent at Park Ridge Country Club in Park Ridge, Ill., since 2005. He is a past president of the Midwest Association of Golf Course Superintendents (1995) and a 38-year year member of GCSAA. He has been a Certified Golf Course Superintendent for 30 years. A version of this article appeared in On Course, the monthly publication of the MAGCS.