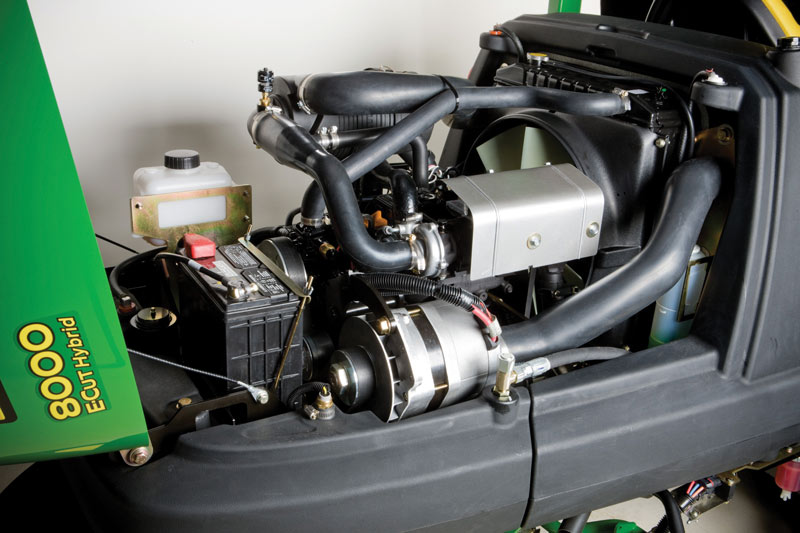

After maintenance equipment has been prepped, cleaned and stored, it should be checked periodically throughout the winter for freezing, cracking and any resulting fluid leaks. Photos courtesy of John Deere Golf

Whether you use your equipment through the winter months or store it, maintenance overhauls are essential. Courses in most regions of the country experience a decrease in play with the change in weather, and equipment maintenance and use plans also adjust. With proper care and storage, superintendents can increase equipment product life and improve performance, season after season.

Turf equipment winter prep checklist

Regardless of your experience with equipment care, always consult the manufacturer’s owner’s manual for best practices for a specific piece of equipment. After you’ve reviewed the manuals and have an idea of each item’s needs, you’ll be able to develop a routine to follow on a seasonal basis.

Gene Westbrook, equipment manager at Sedgefield Country Club in Greensboro, N.C., explains the winter precautions he and his crew take each year: “We generally start the process around October, and we start by treating our gas and diesel fuel with Swepco 503 gasoline and diesel improver. We go through each piece of equipment — service it, and make sure all damages are fixed, fluids are good, batteries are up to strength, and that there’s no corrosion on battery cables or cracking in any of the hydraulic hoses.”

The following fall and winter maintenance tips cover basic recommendations for equipment storage:

• Use a putty knife or wood wedge to remove grass and debris from the bottom of the deck.

• Repair scratched or chipped metal surfaces to prevent rust.

• Remove the deck belt covers and blow off the top of the deck. Inspect belts and replace if worn or frayed.

• Grease the mower deck spindles.

• Inspect blades and sharpen or replace any that are worn, cracked or bent.

• Change the engine oil and filter.

• Clean spark plugs. Re-gap or replace the plugs.

• Review the service charts or owner’s manual, and grease the machine as directed.

• Remove and clean batteries; place on a trickle charger.

• Prevent batteries from being exposed to freezing temperatures.

• Spray a preservative on tires, belts, hoses and the seat.

• Store the unit inside, or cover it well if outside.

• Winterize spray equipment to keep components from freezing and cracking.

Engine storage for winter

Equipment with liquid-cooled diesel engines requires a few additional winterization steps:

• Invest in a hydrometer, and check coolant levels prior to the arrival of freezing weather. Typically a 50/50 mix of coolant/water is adequate in the lower 48 states. Too much antifreeze can actually harm engines, because it does not shed heat as well as water does.

• If the machine will be out of operation, top off the fuel tank to prevent condensation of moisture in the tank. Add a diesel fuel stabilizer, and run the engine to allow it to circulate through the system.

• Remove the battery and place in a warm spot. Trickle-charge it through the season.

• Replace engine oil and filter.

• Replace the air cleaner elements as well as the hydraulic filter and axle oil strainers if present. Any moisture in an engine oil can be very harmful to engine components if the tractor is idle for several months.

Winterization of stored turf maintenance equipment should focus on preventing the batteries from being exposed to freezing temperatures. Batteries should be removed, cleaned and placed on a trickle charger.

If the weather in your area is particularly harsh and you won’t be using your mowers for 60 days or more, be sure to follow these tips before storing:

• Change engine oil and filter while the engine is warm.

• Service the air filter if necessary.

• Clean debris from engine air intake screen.

• On gas engines, remove spark plugs and put 30 milliliters (1 ounce) of clean engine oil in cylinders. Install spark plugs, but do not connect spark plug wires. Crank the engine five or six times to allow the oil to be distributed.

• Clean the battery and battery posts. Check the electrolyte level if your battery is not maintenance-free.

• Close fuel shut-off valve if your machine is equipped.

• Store the battery in a cool, dry place where it will not freeze (a stored battery should also be recharged every 90 days).

• Charge the battery.

“We always check on our stored equipment throughout the winter,” says Westbrook. “And as the weather changes, we’ll move sprayers and the like inside on colder days, just to ensure there’s no freezing or cracking.”

After equipment has been stored, regularly check the floor underneath the machines throughout the season for any small puddles that would indicate leaks. This precautionary step will make you aware of any damages during the storage period — not on the first day of spring.

Steeling against winter weather

Beyond equipment storage, courses in some regions need to take necessary precautions to manage severe weather and ensure the facility is in the best possible shape. As a best practice, managers in cold climates should prepare any machinery that may be needed for facility maintenance. Tractors are often employed for snow removal or spreading salt. When the forecast calls for snow or ice, it’s important that the tractor be ready and waiting.

“In the winter when we are expecting severe weather, we bring our John Deere 310G backhoe inside to ensure it is warm and ready for use,” Westbrook says.

Specifically, be sure to check the tractors’ implements. For example, hydraulic cylinder rods should be coated with beeswax-based preservatives to prevent pitting or corrosion. In addition, cover quick-connect hydraulic couplings as well as the electrical connectors with a rubber dust cover, or wrap them in plastic to prevent intrusion of rain or dirt. It’s always a good idea to inspect tire chains that may be used occasionally for traction on snow and ice.

Utility vehicles may also be required for limited use. Make sure the vehicle is winter-ready by servicing the engine, changing the oil, and replacing the spark plugs, air cleaner and fuel filter. If the machine is only occasionally used, leave a trickle charger connected to the battery while it remains in the vehicle. If the vehicle has a cab, inspect and test the heater, wipers and windshield defroster.

Even if you don’t expect severe weather or don’t plan to use a utility vehicle over the colder months, it still needs maintenance checks to prepare for longer periods of storage. When this is the case, start by lubricating the chassis and suspension, and storing the battery. As you would for any other piece of equipment, clean the bed of dirt and debris, and wash any fertilizer or chemical residues from the vehicle. Water-cooled vehicles should have the cooling system inspected and the antifreeze tested. In addition, spray preservatives on tires, belts and hoses.

Talk to your dealer

Your local equipment dealer can be a valuable resource for tips and best practices related to equipment storage, equipment maintenance and course care during winter. Not only is the dealer your primary source for specific manufacturer information and recommendations, but as a representative in your region, he or she will be able to provide further details on what works for other facilities in your area, as well as what to avoid.

As the snow melts and spring slowly arrives, players will be eager to get on the greens and enjoy the warmer weather. Thorough equipment maintenance at the start of each winter will ensure your equipment is ready to produce the pristine results golfers enjoy.

Tracy Lanier is product manager for John Deere Golf.