Two shade structures were built to provide 80% shade cover for a Vesper velvet bentgrass and a Tyee creeping bentgrass putting green at the O.J. Noer Turfgrass Research and Education Facility in Madison, Wis. Photos by Ben Pease

Nearly all cool-season golf and some warm-season golf is played on creeping bentgrass (Agrostis stolonifera) greens, and in many cases, these greens are subjected to some level of shade stress. While some superintendents have unlimited use of chain saws, or what a previous supervisor called “Thunder” and “Lightning,” many superintendents have restricted access to them as shade management tools. In such cases, management of shaded creeping bentgrass greens can be difficult, time-consuming and input-intensive. Shaded greens often require irrigation, fertility, cultural and chemical regimes that differ from those for full-sun greens. Even with all of this effort, the results may still be subpar.

Creeping bentgrass is an excellent putting green turfgrass, but is there another turf that will provide better playing conditions in shade?

Velvet bentgrass

Velvet bentgrass (A. canina) is a possible alternative that may have input requirements similar to or lower than creeping bentgrass. Currently used only in the northeastern and northwestern areas of the United States, velvet bentgrass was originally planted as South German bentgrass (75% colonial bentgrass, 15% velvet bentgrass, 1% creeping bentgrass, plus many impurities) in the early 1900s and saw extensive use on golf courses for the early half of the 20th century (5).

As new seeded cultivars of creeping bentgrass were released, velvet bentgrass fell out of favor, possibly because management practices were not well understood (3). Management of velvet bentgrass differs slightly from that of creeping bentgrass because of velvet bentgrass’s high density and extremely fine texture. Overwatering and overfertilizing were also possible reasons for its decline in popularity.

Why take another look at velvet bentgrass? If it did not work in the second half of the 20th century, why would it now?

Thanks to a resurgence of velvet bentgrass research in the 1990s and beyond, we now know much more about its proper management in modern golf turf situations (2). New velvet bentgrass cultivars, such as SR 7200, Legendary and Vesper, exhibit a more desirable dark green color than the earlier cultivars (2, 11). Modern velvet bentgrass cultivars also have comparable or better wear tolerance (4, 12) and require no more nitrogen than creeping bentgrass (1, 7). Velvet bentgrass also uses less water than other bentgrass species (6) and is a top performer in low-input fairways (13). Recent research has shown that velvet bentgrass maintains acceptable putting green turf quality on soils outside the coastal regions of the northern United States (7, 8).

Most important, velvet bentgrass may be more shade-tolerant than creeping bentgrass (10), with preliminary tests showing SR 7200 velvet bentgrass to be more shade-tolerant than Penncross creeping bentgrass at fairway/tee height (personal observation).

Because of our improved understanding of velvet bentgrass input requirements and the improved color of modern cultivars, velvet bentgrass can be properly managed to provide playing conditions and appearance equal to those of creeping bentgrass. Therefore, the goal of this research was to compare the relative shade tolerance of these two bentgrass species in an effort to determine the best bentgrass for shaded putting green situations.

Our experiment

Vesper velvet bentgrass and Tyee creeping bentgrass were established on a native soil push-up green at the O.J. Noer Turfgrass Research and Education Facility near Madison, Wis. Two hoop houses (each 30 feet wide × 45 feet long × 15 feet high; 9.1 × 13.7 × 4.5 meters) were constructed above the green to provide support for shade cloth simulating 80% shade. Treatments of bentgrass species, nitrogen rates and Primo Maxx (trinexapac-ethyl, Syngenta) rates were arranged in a randomized complete block, strip-split plot design with four replications.

Bentgrass species served as whole-plot treatments, and each was randomly split to receive one of two trinexapac-ethyl rates (0.0 and 0.125 ounce/1,000 square feet; 0.0 and 0.38 liter/hectare). Three annual nitrogen rates (1, 2 and 4 pounds/1,000 square feet; 49, 98 and 196 kilograms/hectare) were stripped across the bentgrass species and trinexapac-ethyl rates. Plots were maintained at 0.125-inch (3.2-mm) height of cut using a Toro walk-behind reel mower, and were irrigated at 40% ET replacement. Nitrogen treatments were applied at 14-day intervals (using urea as the nitrogen source), and trinexapac-ethyl was applied every 28 days, both beginning for each growing season on May 15, 2009, and May 3, 2010.

Black shade cloth was installed over both hoop houses from May 10 to Oct. 25, 2009, and from May 13 to Oct. 18, 2010, to reduce photosynthetically active radiation (PAR) by approximately 80%. The installment and removal dates corresponded with area of spring tree leaf development and fall tree leaf senescence. Of particular note is that 80% shade cloth provided more than 80% shade when compared with calculated 80% of full sun PAR values (Figure 1) (9).

Nitrogen rate effect

The amount of nitrogen fertilizer had a greater effect than Primo applications on turf quality of both bentgrasses. Fertilization at the high rate of 4 pounds/1,000 square feet (196 kilograms/hectare) resulted in turf declining to less-than-acceptable quality by midsummer of the first year, while the other fertilization rates of 1 and 2 pounds/1,000 square feet (49 and 98 kilograms/hectare) held acceptable quality through early September (Figure 2).

Declines in turf quality in the second year were less severe, but all rates ended with unacceptable quality. The best fertility rate for both species under 80% shade was 1 pound nitrogen/1,000 square feet. This confirms that fertility inputs must be reduced for shaded turf. Overfertilization results in turfgrass plants depleting their carbohydrate reserves and becoming unable to generate adequate replacements.

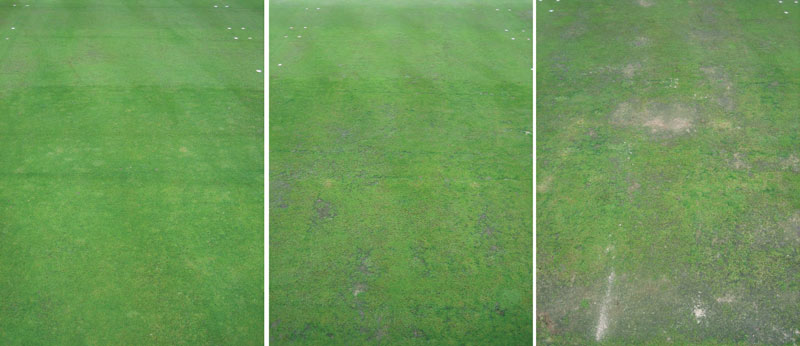

In the first year of the study, plots fertilized at the lower rates (left, 1 pound of nitrogen/1,000 square feet; middle, 2 pounds of nitrogen/1,000 square feet) had acceptable turf quality through early September, but plots treated at the high rate of nitrogen (right, 4 pounds of nitrogen/1,000 square feet) had less-than-acceptable quality by midsummer.

As turf quality decreased throughout the trial, so did clipping yield. Used as an indicator of turf health, clipping yield confirmed the unacceptable turf quality of higher fertility rates, with 1 and 2 pounds nitrogen/1,000 square feet producing greater clipping yields than 4 pounds nitrogen/1,000 square feet.

Ball roll distances (green speed) were mostly similar at all fertility rates in the first year. When differences did occur in both years, ball roll distances increased as nitrogen rate increased. This is the opposite of what other researchers reported for velvet bentgrass in full sun (8) because, in this trial, the turf treated at rates of 2 and 4 pounds/1,000 square feet had much lower percent ground cover and therefore less turf resistance and higher ball roll distances than the turf treated with 1 pound nitrogen /1,000 square feet.

Addition of trinexapac-ethyl

Shaded bentgrass treated with trinexapac-ethyl had higher quality and held that quality for a longer duration than non-treated turf in the first year. This was true for both bentgrass species. In the second year, when trinexapac-ethyl treatments differed, turf treated with trinexapac-ethyl had significantly higher turf quality than the non-treated turf. In the second year, the highest turf quality was achieved with 1 pound nitrogen/1,000 square feet and the addition of trinexapac-ethyl. No differences in turf quality response by bentgrass species is good information for superintendents, because trinexapac-ethyl product labels do not differentiate between bentgrass species.

Trinexapac-ethyl did not have a consistent effect on clipping yield because turf quality for most treatments declined quickly and was greatly influenced by fertility rate. Shortening the trinexapac-ethyl application interval could have resulted in a more consistent clipping yield response and, likely, increased turf quality ratings. Trinexapac-ethyl also did not have a consistent effect on ball roll distance because turf uniformity was poor.

Species effect

In the first year, the decline in turf quality was faster and greater for velvet bentgrass than for creeping bentgrass. In the second year, this trend was reversed (Figure 3). Although both species declined to unacceptable quality by the end of the second year, velvet bentgrass quality declined more slowly and ended slightly higher than creeping bentgrass quality.

Based on these trends, velvet bentgrass quality might have increased if the trial were continued for a third and fourth year, and if we were able to incorporate additional cultural practices to encourage recovery in turf quality. This data is only from one newer cultivar of each species. If we had tested Vesper velvet bentgrass against an older, more commonly used creeping bentgrass cultivar, more differences might have been seen. In addition, anecdotal evidence released after our trial suggests that Tyee creeping bentgrass is a shade-tolerant cultivar.

Clippings were collected on 13 dates in each year of the study to determine clipping yields for each species.

Bentgrass species did not have a consistent effect on clipping yield. While clipping yield should reflect the slightly higher turf quality of velvet bentgrass in the second year, both species had similar clipping yields for the entire season. This might be due to the finer texture of velvet bentgrass compared with creeping bentgrass. Even though velvet bentgrass had higher percent ground cover, as assumed through higher quality, this did not translate to higher clipping yields, because velvet bentgrass plants are smaller and finer than creeping bentgrass plants. More velvet bentgrass plants seem to produce the same amount of clippings as fewer, larger creeping bentgrass plants. This is important, because golfers might not notice a difference in overall growth rate between the two species, but they might actually see the higher percent ground cover of velvet bentgrass.

Even more important to golfers and superintendents is ball roll distance. On nearly all rating dates, both species had similar ball roll distances. This is important for superintendents considering velvet bentgrass. If ball roll distances for both species are similar, golfers will not notice the species difference and will not have to alter their putting game — arguably the toughest part of golf to master. Although growth style differs between the species (that is, more extremely fine plants vs. fewer plants with a slightly coarser texture), playability and ball roll distance differences should not be detected by even the most advanced golfer.

The take-home message

Overall turf quality was similar for the two species, and both species responded in a similarly positive manner to trinexapac-ethyl application and lower nitrogen rates. Our information that velvet bentgrass is tolerant to trinexapac-ethyl is helpful for golf course superintendents, as trinexapac-ethyl labels generically list “bentgrass” — not individual Agrostis species — as suitable for treatment. This research shows that our trinexapac-ethyl rate was near the ideal rate for shaded bentgrass turf, but that our trinexapac-ethyl application interval was too conservative. Future trials will address applying trinexapac-ethyl to shaded turf using the now-common practice of scheduling applications by growing degree days.

If a superintendent is not allowed to remove the trees that cause shade stress, velvet bentgrass treated with trinexapac-ethyl and a low rate of nitrogen is a viable alternative to creeping bentgrass. The growth rate (clipping yield) of both species in shade is similar, so golfers should not notice a difference in green speed. Although both species do decline in turf quality over time, velvet bentgrass seems to decline at a slower rate.

In our trial, even as trained golf turf managers, we were not permitted to employ other cultural practices such as overseeding or aeration to reduce turf quality decline or encourage new growth. However, to improve putting green shade tolerance, judicious golf course superintendents could overseed with velvet bentgrass, apply nitrogen at 1 to 1.5 pounds/1,000 square feet/year, and apply trinexapac-ethyl at frequent intervals while following other best management practices for shade, such as reduced irrigation and increased minimally invasive aeration techniques. Pin placement for traffic management should also be considered.

Funding

This research was supported in part by funding from the Wisconsin GCSA and by the College of Agricultural and Life Sciences/Agricultural Research Stations of the University of Wisconsin-Madison, which provided field space.

Acknowledgments

The information in this paper, along with additional data and figures, was originally published as “Nitrogen rate and growth regulator effects on shaded velvet and creeping bentgrass” by B.W. Pease and J.C. Stier. 2018. Agronomy Journal 110:2151-2158. doi:10.2134/agronj2018.01.0071

The research says ...

- Velvet bentgrass, which was used extensively on golf courses in the U.S. from about 1900 to 1950, differs from creeping bentgrass because it has high density and very fine texture.

- When managed properly, velvet bentgrass can provide playing conditions and turf quality equivalent to those of creeping bentgrass.

- Vesper velvet bentgrass and Tyee creeping bentgrass were tested under shade, three fertility rates and trinexapac-ethyl treatment.

- In shade, both species declined over time, but velvet bentgrass appeared to decline more slowly, showing that it could serve as an alternative to creeping bentgrass.

Literature cited

- Boesch, B.P., and N.A. Mitkowski. 2007. Management of velvet bentgrass putting greens. Applied Turfgrass Science 4(1):1-6.

- Brilman, L.A. 2003. Velvet bentgrass (Agrostis canina L.). Pages 201-205. In: M.D. Casler and R.R. Duncan, eds. Turfgrass biology, genetics, and breeding. John Wiley & Sons, Hoboken, N.J.

- Brilman, L.A., and W.A. Meyer. 2000. Velvet bentgrass: Rediscovering a misunderstood turfgrass: Past mistakes have damaged an excellent species’ reputation. Golf Course Management 68(10):70-75.

- Cashel, R.H., H. Samaranayake, T.J. Lawson, J.A. Honig and J.A. Murphy. 2005. Traffic tolerance of bentgrass cultivars grown on a sand-based root zone. International Turfgrass Society Research Journal 10:531-537.

- Christians, N.E., A.J. Patton and Q.D. Law. 2017. Fundamentals of turfgrass management. 5th ed. John Wiley & Sons, Hoboken, N.J.

- DaCosta, M., and B. Huang. 2006. Deficit irrigation effects on water use characteristics of bentgrass species. Crop Science 46:81-89.

- Koeritz, E.J., and J.C. Stier. 2009. Nitrogen rate and mowing height effects on velvet and creeping bentgrasses for low-input putting greens. Crop Science 49:1463-1472.

- Pease, B.W., E.J. Koeritz, D.J. Soldat and J.C. Stier. 2011. Nitrogen source and rate effects on velvet bentgrass putting green turf. Crop Science 51:342-352.

- Pease, B.W., and J.C. Stier. 2018. Nitrogen rate and growth regulator effects on shaded velvet and creeping bentgrass. Journal of Agronomy 110:2151-2158. doi:10.2134/agronj2018.01.0071

- Reid, M.E. 1933. Effects of shade on the growth of velvet bent and Metropolitan creeping bent. Bulletin of the USGA Green Section 13:131-135.

- Rose-Fricker, C.A., M.L. Fraser, W.A. Meyer and S.A. Bonos. 2004. Registration of ‘Greenwich’ velvet bentgrass. Crop Science 44:349-350.

- Samaranayake, H., T.J. Lawson and J.A. Murphy. 2008. Traffic stress effects on bentgrass putting green and fairway turf. Crop Science 48:1193-1202.

- Watkins, E., A.B. Hollman and B.P. Horgan. 2010. Evaluation of alternative turfgrass species for low-input golf course fairways. HortScience 45:113-118.

Ben W. Pease is a research assistant and doctoral student in the Department of Horticulture at Iowa State University, Ames, Iowa. John C. Stier is a professor in the Department of Plant Sciences and associate dean for academic affairs in the Herbert College of Agriculture at the University of Tennessee, Knoxville, Tenn.