Figure 1. Experimental putting green in Knoxville, Tenn., including the zoysiagrass cultivars Lazer, M85, Prizm and Trinity. Photo by Tyler Carr

Zoysiagrass is a rhizomatous and stoloniferous perennial turfgrass that is well adapted to transition and warm climatic areas in the United States. Zoysiagrasses provide a range of leaf textures that are used in varying applications, from commercial and

residential lawns to golf course fairways and tees. In areas of the U.S. where zoysiagrass is utilized, hybrid ultradwarf bermudagrass is the predominant warm-season turfgrass species on golf course putting greens (1).

Ultradwarf bermudagrass has poor shade tolerance, which can limit its use on shaded putting greens (2). Diamond zoysiagrass is a fine-textured Zoysia matrella cultivar released in 1996 that has demonstrated greater shade tolerance than bermudagrass and

can tolerate mowing heights typical for golf course putting greens (3). However, Diamond has demonstrated a maximum ball roll distance (BRD) of 8.5 feet (2.6 meters) when maintained at 0.100 inches (2.54 millimeters) (9).

Recent developments in zoysiagrass breeding have led to the release of fine-textured cultivars that may have improved performance as a putting surface. Bladerunner Farms (Poteet, Texas) developed and released three Z. matrella cultivars for putting green

use: Trinity (L1F), M85 and Prizm (M-60). Also, Texas A&M University released a Z. matrella × Z. minima hybrid, Lazer (DALZ 1308), in 2020.

In addition to improved shade tolerance of zoysiagrass compared to ultradwarf bermudagrass, zoysiagrass has slower growth rates than bermudagrass, leading to reduced nutrient requirements (6). Previous research has recommended that yearly nitrogen inputs

for Diamond putting greens in the transition zone should begin at 1.5 pounds per 1,000 square feet (7.3 grams per square meter) during the summer months to maximize playability and quality (7). Determining the optimal nitrogen requirements for individual

putting green cultivars can help golf course superintendents reduce fertilizer inputs without affecting playability.

The performance and quality of turfgrass species or cultivars is paramount when determining their suitability for golf course putting greens. Specifically, performance factors that golf course superintendents can directly manage include green speed and

firmness (4). Typically, faster green speeds are associated with more difficulty. Additionally, putting greens that are less firm will reduce the distance the golf ball travels after contacting the surface (4). The normalized difference vegetation

index (NDVI) can be utilized to assess turfgrass color, a metric of turfgrass quality.

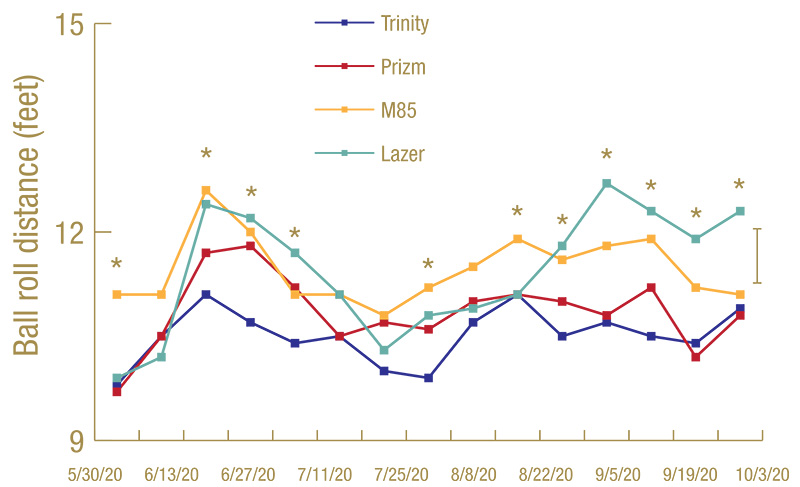

Figure 2. Ball roll distance of zoysiagrass cultivars Lazer, M85, Prizm and Trinity over the 2020 growing season in Knoxville, Tenn. Data are pooled across nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet applied every two weeks. Error bar indicates least significant difference for comparing means, and asterisks denote dates with significant differences among treatments (P ≤ 0.05).

Materials and methods

To assess zoysiagrass for potential use on putting greens, a field experiment was conducted at the East Tennessee AgResearch and Education Center in Knoxville, Tenn., in 2020 and 2021 on a root zone containing an 85:15 (v:v) mixture of sand meeting USGA

particle-size specifications and reed sedge peat moss overlaying subsurface drainage (10). During the growing season (May through October), plots were mowed at 0.115 inches (2.921 millimeters) five times weekly using a walk-behind reel mower (Greensmaster

Flex 2100, The Toro Co., Bloomington, Minn.) with clippings removed. Plots were also rolled five times weekly using a Golf Green Roller (RB48; Tru-Turf, Arundel, Australia).

This study evaluated four zoysiagrass cultivars for putting green use (Figure 1). Individual 5-foot-by-15-foot (1.5-meter-by-4.6-meter) plots containing Trinity, M85, Prizm or Lazer zoysiagrass were planted by sprigs at 1,200 bushels per acre (109 cubic

meters per hectare) in June 2018. Two rates of nitrogen fertilizer rates (0.19 and 0.38 pounds nitrogen per 1,000 square feet; 0.93 and 1.86 grams nitrogen per square meter), totaling 1.5 and 3.0 pounds nitrogen per 1,000 square feet (7.4 and 14.9

grams nitrogen per square meter) were applied to each cultivar every two weeks over the 16-week period, beginning June 5, 2020, and June 11, 2021. Soluble urea (46% nitrogen–0% phosphorous–0% potassium) was applied using a CO2-pressurized

plot sprayer with flat fan nozzles (XR8006; TeeJet, Springfield, Ill.) delivering 30 gallons per acre (281 liters per hectare) of spray volume.

>Data was collected weekly on golf course putting green performance and quality characteristics during 2020 and 2021. Ball roll distance was measured weekly using the Stimpmeter (USGA, Liberty Corner, N.J.), which is a tool to evaluate the speed of

putting greens by applying a known velocity to a golf ball and measuring the distance traveled (8). Surface firmness (FieldScout TruFirm Turf Firmness Meter; Spectrum Technologies Inc., Aurora, Ill.) and turfgrass color (FieldScout TCM 500 NDVI Turf

Color Meter; Spectrum Technologies Inc., Aurora, Ill.) were also evaluated weekly until the conclusion of the trial.

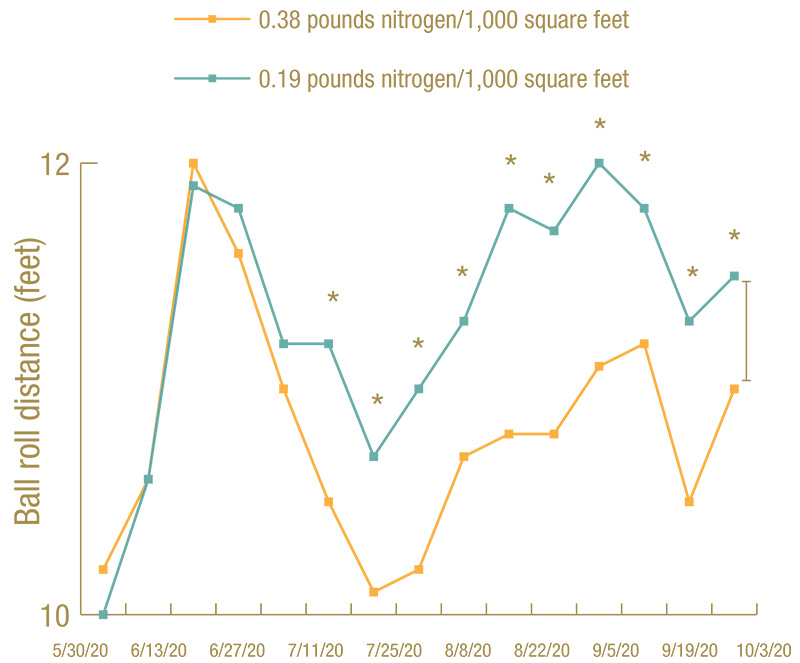

Figure 3. Ball roll distance of zoysiagrass when receiving nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet every two weeks over the 2020 growing season in Knoxville, Tenn. Data are pooled across the zoysiagrass cultivars Lazer, M85, Prizm and Trinity. Error bar indicates least significant difference for comparing means, and asterisks denote dates with significant differences among treatments (P ≤ 0.05).

Results

Ball roll distance

Each zoysiagrass cultivar affected ball roll distance during the experiment. In 2020, all cultivars had BRD greater than 10 feet (3 meters), with the exception of the first evaluation date and Trinity on two other dates (Figure 2). Either Lazer or M85

had the greatest BRD, averaging 11.4 and 11.5 feet (3.47 and 3.51 meters) across all evaluation dates. In fact, BRD for Lazer and M85 significantly differed on five evaluation dates by an average of 1 foot (0.3 meters), which may be difficult for

golfers to distinguish (5). Ball roll distance in 2021 (data not shown) followed a similar trend as 2020, with Lazer and M85 averaging the greatest BRD (11.4 and 10.8 feet; 3.47 and 3.29 meters). Lazer had significantly greater BRD than Prizm (10.4

feet; 3.17 meters) and Trinity (10.3 feet; 3.14 meters).

Ball roll distance was significantly affected by nitrogen rate throughout the study. Over the last 10 evaluation dates in 2020 and three separate nitrogen applications, the lower nitrogen rate averaged BRD of 11.4 feet (3.47 meters) compared to 10.7 feet

(3.26 meters) for the higher nitrogen rate (Figure 3). Similar to 2020, nitrogen rate also significantly affected BRD in 2021. Applying the lower nitrogen rate resulted in BRD of 11.3 feet (3.44 meters) compared to 10.1 feet (3.08 meters) for the

higher nitrogen rate (data not shown).

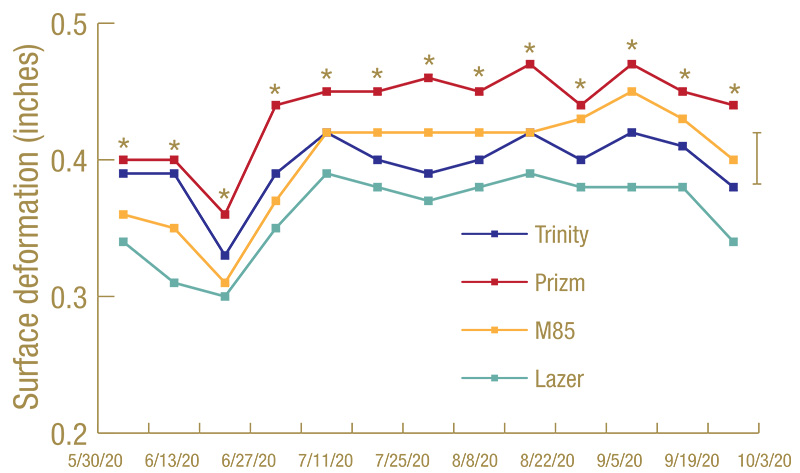

Figure 4. Surface deformation for Lazer, M85, Prizm and Trinity zoysiagrass over the 2020 growing season in Knoxville, Tenn. Data are pooled across nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet applied every two weeks. Error bar indicates least significant difference for comparing means, and asterisks denote dates with significant differences among treatments (P ≤ 0.05).

Surface firmness

Cultivar significantly affected surface firmness on each of the 13 evaluation dates in 2020 (Figure 4). Generally, Prizm had the greatest depth of penetration (softest surface), averaging 0.08 inches (2.03 millimeters) greater penetration than Lazer,

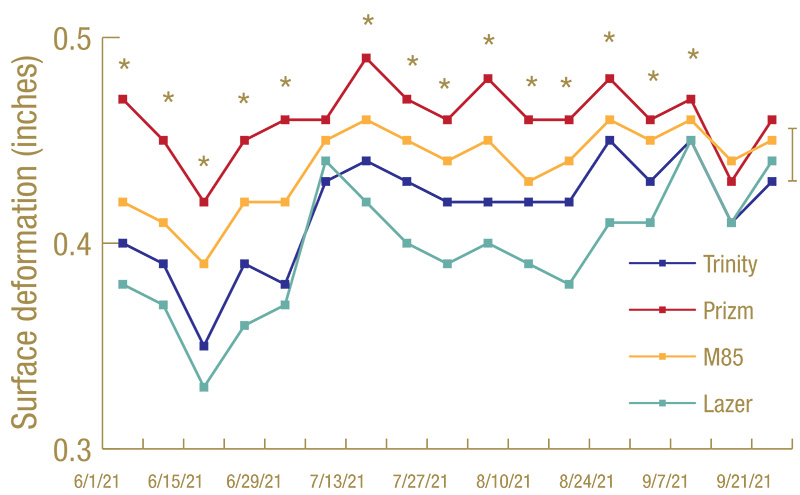

the firmest surface. Prizm and M85 had similar surface firmness from Aug. 25 through Sept. 9. Cultivar affected surface firmness similarly in 2021, as there were significant differences among treatments on 14 of the 17 evaluation dates (Figure 5).

Prizm averaged 0.07 inches (1.78 millimeters) greater surface penetration than Lazer during that period, which is numerically similar to the differences found in 2020.

In 2020, nitrogen rate significantly affected surface firmness on one evaluation date; therefore, the fertilizer treatments were not practically different in the 2020 growing season. In 2021, the highest nitrogen rate provided significantly greater surface

penetration (0.44 inches; 11.05 millimeters) than the lowest nitrogen rate (0.42 inches; 10.67 millimeters) (data not shown). These differences likely have limited practical value since penetration differences of 0.015 inches (0.38 millimeters) may

be difficult for golfers to distinguish.

Figure 5. Surface deformation for Lazer, M85, Prizm and Trinity zoysiagrass over the 2021 growing season in Knoxville, Tenn. Data are pooled across nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet applied every two weeks. Error bar indicates least significant difference for comparing means, and asterisks denote dates with significant differences among treatments (P ≤ 0.05).

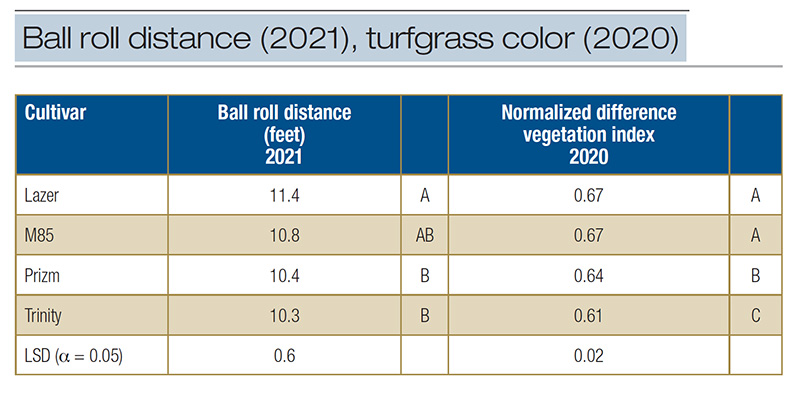

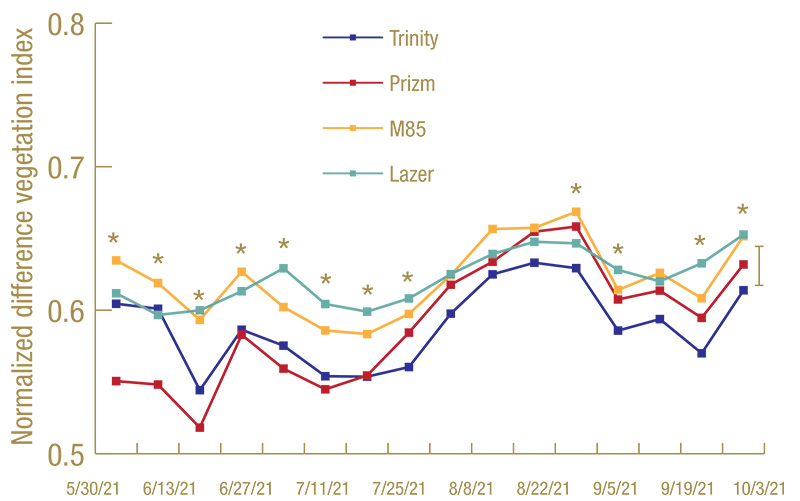

Turfgrass color

In 2020, Lazer and M85 had the greatest NDVI values (0.67) of all cultivars (Table 1). These values were significantly greater than Prizm (0.64), which was greater than Trinity (0.61). Significant differences in turfgrass color were present among cultivars

on 12 of the 16 evaluation dates in 2021 (Figure 6). During that period, Lazer and M85 had significantly different NDVI values on only July 5, indicating that Lazer and M85 had similar levels of turfgrass color during both years. Additionally, Prizm

had similar turfgrass color to Lazer or M85 on all but one of the last nine evaluation dates.

At this point, the experimental putting green had been established for approximately three years. While not an objective of this study, these data show that Lazer, M85 and Prizm may all offer similar turfgrass color in the long term. Contrarily, Trinity

consistently exhibited the lowest turfgrass color in 2021, averaging an NDVI value of 0.59. The results from this study imply that Trinity, while providing a firm putting surface, consistently provided reduced turfgrass color compared to the other

cultivars tested.

The nitrogen treatments in this study had significant effects on turfgrass color. In 2020, when pooled across all zoysiagrass cultivars and evaluation dates, the higher nitrogen rate resulted in an NDVI value of 0.67, which was greater than the lower

rate (0.63) (data not shown). While differences of 0.04 units are small numerically, visual differences were observed between treatments and therefore quantified using NDVI. In 2021, nitrogen rate significantly affected turfgrass color on all 16 evaluation

dates, with the higher nitrogen rate averaging NDVI values of 0.64 compared to 0.58 for the lower nitrogen rate.

Table 1. Ball roll distance (2021) and turfgrass color (2020) determined by normalized difference vegetation index of the zoysiagrass cultivars Lazer, M85, Prizm and Trinity in Knoxville, Tenn. Data are pooled across all evaluation dates and nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet applied every two weeks. Treatments with similar lettering are not significantly different (P ≤ 0.05).

Final thoughts

Intensive daily management practices, such as low mowing and lightweight rolling, will likely be necessary to maintain BRDs greater than 10 feet (3.05 meters). Nitrogen fertilizer practices will affect BRDs, but an input of 0.19 pounds nitrogen per 1,000

square feet every two weeks over 16 weeks resulted in reduced turfgrass color. However, it is unknown how zoysiagrass putting greens will respond to nitrogen applied at rates between those tested in the present study. Additionally, nitrogen requirements

for zoysiagrass putting greens should be explored under varying mowing and/or rolling frequencies, which may reduce labor inputs if putting green performance parameters are consistent.

All cultivars tested in this study provided BRDs greater than previously reported values for Diamond. Also, the zoysiagrass cultivars tested in the present study offered varying levels of putting green performance and turfgrass color. Under the conditions

tested, Lazer and M85 consistently exhibited greater BRD and turfgrass color than Prizm or Trinity. Prizm had similar turfgrass color to Lazer and M85 but lacked the BRD that the other cultivars provided. However, Prizm may be selected in situations

where a less firm putting surface is desired. Trinity is not recommended for use on putting surfaces, as turfgrass color and performance were both reduced compared to Lazer, M85 and Prizm.

Figure 6. Turfgrass color determined by normalized difference vegetation index of the zoysiagrass cultivars Lazer, M85, Prizm and Trinity during the 2021 growing season in Knoxville, Tenn. Data are pooled across nitrogen rates of 0.19 and 0.38 pounds nitrogen per 1,000 square feet applied every two weeks. Error bar indicates least significant difference for comparing means, and asterisks denote dates with significant differences among treatments (P ≤ 0.05).

The Research Says

- Ball roll distance was significantly affected by nitrogen rate throughout the

study.

- Generally, Prizm had the greatest depth of penetration (softest surface), averaging

0.08 inches (2.0 millimeters) greater penetration than

Lazer, the firmest surface.

- Lazer and M85 had the greatest NDVI values (0.67) of all cultivars. These values

were significantly greater than Prizm (0.64), which was

greater than Trinity (0.61).

- Trinity is not recommended for use on putting surfaces, as turfgrass color

and performance were both reduced compared to Lazer, M85

and Prizm.

Funding

This research was supported by Bladerunner Farms.

The original article can be found here:

Carr, T.Q., J.C. Sorochan and K.H. Dickson. 2022. Nitrogen rate and cultivar effects on zoysiagrass putting greens in the transition zone. Crop Science (https://doi.org/10.1002/csc2.20805).

Literature cited

- Brosnan, J.T., J.B. Peake and B.M. Schwartz. 2022. An examination of turfgrass species use on golf course putting greens. Crop, Forage & Turfgrass Management 8(1), e20160 (https://doi.org/10.1002/cft2.20160).

- Bunnell, B.T., L.B. McCarty and W.C. Bridges. 2005. ‘TifEagle’ bermudagrass response to growth factors and mowing height when grown at various hours of sunlight. Crop Science 45(2):575–581 (https://doi.org/10.2135/cropsci2005.0575).

- Engelke, M.C., P.F. Colbaugh, J.A. Reinert, K.B. Marcum, R.H. White, B. Ruemmele and S.J. Anderson. 2002. Registration of ‘Diamond’ zoysiagrass. Crop Science 42(1):304–305 (https://doi.org/10.2135/cropsci2002.3040).

- Hartwiger, C. 2014. The big three of putting green setup: Firmness, slope, and speed. USGA Green Section Record 52(4):1–3.

- Karcher, D.E., T. Nikolai and R. Calhoun. 2001. Golfers’ perceptions of greens speeds vary. Golf Course Management 69(3):57–60.

- Kussow, W.R., D.J. Soldat, W.C. Kreuser and S.M. Houlihan. 2012. Evidence, regulation, and consequences of nitrogen-driven nutrient demand by turfgrass. ISRN Agronomy 2012:1-9 (https://doi.org/10.5402/2012/359284).

- Menchyk, N., D.G. Bielenberg, S. Martin, C. Waltz, H. Luo, F. Bethea and H. Liu. 2014. Nitrogen and trinexapac-ethyl applications for managing ‘Diamond’ zoysiagrass putting greens in the transition zone, U.S. HortScience 49(8):1076-1080

(https://doi.org/10.21273/hortsci.49.8.1076).

- Radko, A.M. 1980. The USGA stimpmeter for measuring the speed of putting greens. Pages 473-476. In J.B. Beard, ed. Proceedings of the Third International Turfgrass Research Conference. Madison, Wis.: ASA, CSSA, SSSA.

- Stiglbauer, J.B., H. Liu, L.B. McCarty, D.M. Park, J.E. Toler and K. Kirk. 2009. ‘Diamond’ zoysiagrass putting green establishment affected by sprigging rates, nitrogen sources, and rates in the southern transition zone. HortScience 44(6):1757–1761

(https://doi.org/10.21273/hortsci.44.6.1757).

- United States Golf Association Green Section Staff. 2018. USGA recommendations for a method of putting green construction. USGA Green Section Record 56(4):1–17.

Tyler Carr (tcarr14@tennessee.edu) is a graduate research assistant, John Sorochan is a distinguished professor and Kyley Dickson is the associate director of the Center for Athletic Field Safety, all in the Department of Plant Sciences, University of

Tennessee, Knoxville, Tenn.