An aerifier in action on the Mississippi State University Golf Course in Starkville, Miss. Photos courtesy of Barry Stewart

Editor’s note: This article was originally published in the spring 2020 issue of Mississippi Turfgrass Magazine, a publication of the Mississippi Turfgrass Association, published by Leading Edge Communications, Franklin, Tenn.

Unlike the soils of most other crops, turfgrass soils are rarely exposed to tillage, and therefore many turfgrass soils become compacted because of traffic. Our cultivation program is our best defense against soil compaction and the myriad problems it can cause.

In turfgrass, nearly everything we do — mowing, fertilizing, topdressing, rolling, playing games, etc. — happens on the horizontal plane. Turfgrass cultivation is one of the few things that happens on the vertical plane (I’ve borrowed this idea from Trey Rogers, Ph.D., at Michigan State University). As we maintain and use turf, downward forces are applied and soil particles are pushed closer together. Soil pores, particularly macropores, are eliminated, and the bulk density of the soil increases.

If we think of an “ideal” soil, we think of one that has 50% pore space and 50% solid space. When we consider that quartz is the dominant mineral in soils, then our ideal soil would have a bulk density of 1.33 grams/cm3 given that the density of quartz is 2.65 grams/cm3 (83 pounds/foot3). A bulk density range of 1.2 to 1.5 grams/cm3 is a good working range for healthy turfgrass. Once bulk densities creep above 1.6 grams/cm3, root growth begins to be affected, and at bulk densities above 1.9 grams/cm3, root growth nearly stops. Roots are not drills — they grow in the pore space, and compacted soils have less and less pore space (particularly macropore space) and therefore limited root growth.

The second benefit of cultivation is the control of thatch and organic matter accumulation. Through cultivation, we break up the organic material accumulating at the turf surface. Sometimes the material is removed when we harvest the cores after aerifying or sweep up the clippings after we vertical-mow or fraze-mow. By keeping the root zone in a favorable state of aeration, organic matter accumulation will be kept to a minimum, as oxidation will proceed at its maximum rate.

As organic matter accumulates and compaction happens, the root zone becomes less well-aerated, organic matter decomposition slows, and organic matter accumulation increases. This leads to more moisture being held in the soil, which makes it more vulnerable to compaction, and thus begins a downward spiral in which turf cover is lost.

I’ve written this article with warm-season grasses in mind. The need for cultivation will vary with grass type and soil type. In general, native soils have a greater need for cultivation than sand-based soils do. It’s ironic that sand-based turf is more likely to receive cultivation than a native soil, but this is probably not surprising given the cost to establish and maintain grass on sand construction. Bermudagrass and zoysiagrass make up the vast majority of sports turf surfaces and require more cultivation. Some St. Augustinegrass and centipedegrass that receive traffic may also need occasional cultivation, but this should be done carefully.

To ensure rapid recovery from any cultural practice, make sure temperatures are favorable for turf growth: 70-degree (F) nights, or days in which the daily high + daily low temperatures sum to 150 or more, with plenty of water available.

Core cultivation/hollow-tine cultivation

Hollow-tine cultivation is the cornerstone of any cultivation program. It should be a “showstopper” in that it should be a scheduled event. My mind’s picture of the benefit of core cultivation is that as our turfgrass soil becomes compacted, the elevation of our surface declines. When we pull cores, we create a new, large pore (the hole) and bring material back to the surface. As the cores are broken up and dragged back into the holes, not all the material will fit into the holes, and some will remain on the surface, adding elevation to the surface. If the cores are collected and new material is topdressed onto the site, it’s likely that enough material will be added to provide an increase in surface elevation.

Core cultivation equipment has come a long way since John Mascaro introduced the first vertical overhead aerifier in the 1940s. Prior to this, the tool of choice was a rolling aerifier. Modern aerification equipment works smoothly and features a wide range of tine diameters to choose from. Core diameters can range from 5 millimeters to 25 millimeters. Working depths can range from 25 millimeters to 250 millimeters. Depths longer than about 4 inches (100 millimeters) are considered “deep tine” aerification.

An old-school rolling aerifier still in working order. Turfgrass aerification technology has improved greatly over the years.

Following the introduction of aerifiers, compacted cultivation pans began to form after several years of aerification at the same depth. Incorporating occasional deep-tine aerification into a program breaks up this pan and keeps it from becoming problematic. Hole spacing can range from 1 inch × 1 inch (25 millimeters × 25 millimeters) to 6 inches × 6 inches (150 millimeters × 150 millimeters) and is determined by spacing on the machine and ground speed. In general, as tine size decreases, so does tine spacing. It would be reasonable to pull 3/8-inch (9-millimeter) cores on 1-inch centers, but unreasonable to pull them on 6-inch centers. Likewise, pulling 3/4-inch cores on 1-×-1-inch centers is unreasonable.

Solid-tine cultivation

Solid-tine cultivation produces a hole but does not remove a core. As the walls of the hole slough off and fill the hole over time, compaction is relieved and a zone of better aeration is created.

Solid-tine cultivation can be a very valuable tool in loosening up severely compacted areas to allow hollow-tine coring. Solid-tine cultivation improves soil aeration but does not remove any material from the profile, therefore it has a minimal effect on thatch and organic matter accumulation. It does break up layering and improves infiltration and drainage. The larger the tine, the longer-lasting the effect will be.

Editor’s note: Three veteran turf managers take you inside their approaches to aerification, discussing tines, timing, topdressing, regional considerations and more, in The hole story: Turf managers talk aerification.

Solid-tining has the advantage of no cores to process and no cleanup. The fields or greens are immediately playable. Whether topdressing should follow solid-tining is debatable. Topdressing will smooth out the surface and fill the holes, which could aid playability; however, it also adds material to the soil profile, which means it increases the soil’s density. Perhaps as a once-in-a-while practice, this may be allowable, but it should not be an every-time practice. Also, some hollow-tining must be incorporated into such a process to remove some material.

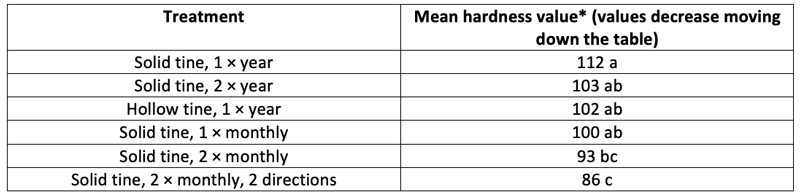

In 2002, we did an experiment at the Mississippi State University Golf Course in Starkville, Miss., that examined aerification frequency (Table 1, below). We used six treatments and replicated each on three greens. We used 6-inch-long × 1/2-inch tines. We found solid-tining twice monthly in two directions reduced greens hardness the most. There was not a great amount of separation among these treatments.

Table 1. Results of a study on golf greens at Mississippi State University Golf Course in 2002.

* Mean hardness values followed by the same letter are not different at the 0.05 level of significance.

Vertical mowing

Vertical mowing is a cultivation tool more focused on thatch and organic matter accumulation than on improving the physical condition of the soil, although it does have an effect on breaking up layering near the surface.

A fairway/athletic field vertical mower ready to go to work.

Vertical mowing equipment ranges from greens equipment with thin blades and narrow spacings to larger-area models with thicker blades and wider spacings. Think of circular saw blades. These blades spin into the canopy and remove material while also severing stolons and rhizomes. Working depths can range from a surface tickle to about 1 inch deep. Deep depths generate more material that must be removed to make the surface playable again.

Vertical mowing is often followed by topdressing to smooth out the surface. During the growing season, some golf courses lightly vertically mow and topdress greens weekly to control grain and organic matter accumulation. Fairways and athletic fields would benefit from vertical mowing once or twice during the growing season. To ensure rapid recovery from vertical mowing, make sure temperatures are favorable for turf growth: 70-degree (F) nights, or days in which the daily high + daily low temperatures sum to 150 or more, with plenty of water available.

Fraze mowing

Fraze mowing is much like vertical mowing except that fraze mowing completely removes all surface materials to a set depth. Fraze mowing can be used to remove just the verdure and the thatch/mat layer, or it can be done as deep as 2 inches below the soil surface. The material removed flows onto a conveyor belt and is deposited in a debris wagon for disposal.

A fraze mower removes dead bermudagrass for the resurfacing of Davis Wade Stadium at Mississippi State University.

In many cases, the material removed is a fantastic source of sprigs that could be used to plant or renovate a nearby field. Fraze mowing generates large amounts of clippings/spoils that must be disposed of, and planning for that should be part of the process. Fraze mowing will remove surface layering, thatch and accumulated soil organic matter. The regrowth from fraze mowing can take as little as 21 days to as long as six weeks.

In Matt Carpenter’s research on fraze mowing at MSU (1), we found that the practice was very effective in removing overseeding in the month of May. Fraze mowing was also found to be an effective way to establish overseeding in fall, with a mid-October date being most effective.

Keep in mind that a field will not be playable for at least three weeks following fraze mowing. Fraze mowing may not be an every-year tool, but it’s certainly one to consider occasionally as a field renovation. Fraze mowing produces a clean, new surface that is free of senescent leaves for a few weeks, and during that time, the field looks outstanding. Fraze mowing has proved to be very effective in removing a dead surface in a renovation process.

A leveling fraze mower removes a lip from an infield.

Some fraze mowing equipment, such as the Turfplaner, has the ability to level while fraze mowing. These machines have great utility in removing lips on baseball and softball fields as well as helping maintain field smoothness.

Rotary decompaction

I think of these machines as being like the plows and deep-ripping subsoilers used to remove compaction pans from agricultural fields. Rotary decompactors are beginning to be used more to remove compaction from fairways and athletic fields.

The knives of a rotary decompactor. The machine makes continuous slits in the soil while quaking the soil between the knives.

A blade that is 10 to 12 inches long is rotated into the soil, and the arrangement of the blades along the shaft produces a quaking action as the machine moves forward. The result is a continuous slit in the soil on 8- to 12-inch spacings. This does very little to remove thatch, but it does loosen up a surface. Research is needed to document the compaction relief achieved and the longevity of this relief.

Some companies have paired rotary decompactors with a sand hopper to inject sand into the slits. This allows the slits to stay open for a longer period of time and remain effective longer. Using one of these machines perpendicular to the crown on an athletic field may be a way to enhance internal drainage.

Sand injection

Sand-injection machines (such as the DryJect) have the old Toro HydroJect in their lineage. High-pressure water is used to create a hole, and the hole is then filled with dry sand or other dry soil amendments.

A DryJect machine on the Mississippi State University Golf Course.

These machines are mostly used on golf greens, but larger models are available for fairway and athletic field use. Although the devices do offer some compaction relief, the sand injection is also used to tighten up golf greens after hollow-tine aerification. Additionally, the sand injection provides a small amount of thatch/soil organic matter control via dilution. Similar to solid-tine aerification followed by topdressing, a hole is being made and filled with material, and no material is being removed. Frequent use of this strategy without pulling a core at some point should lead to an increase in bulk density.

In a DryJect study on athletic fields at Mississippi State, “dryjection” five times per season and hollow-tining two times per season increased bulk densities compared with hollow-tining alone (2).

Slicing and spiking

Slicers and spikers produce small holes or slits in the soil in a linear pattern. They do not have much effect on removing compaction or removing thatch. They do create holes and slits that allow the soil to breathe a bit until they are closed by traffic.

An example of a slicer/spiker machine.

These machines cover a lot of ground quickly and can be used fairly frequently, and there is often little to no recovery time or disruption to play. They’re a good tool during the spring transition to do some “venting” and can also be used in the establishment of overseeding. The MSU campus landscape department has an AERA-vator that they often use ahead of fall overseeding. The first seeds to germinate are usually the ones in the holes created by this machine. Slicers and spikers are also good tools for opening up the canopy.

In sum, hollow-tine coring is the backbone of a cultivation program, and at least one if not two coring events should take place most years. Make this event a “showstopper.” In addition to the coring event, there are many other cultivation tools that are less disruptive and can be used more frequently. If compaction is the main problem, solid-tine aerification or rotary decompaction may be of benefit. If thatch and organic matter are a problem, then vertical mowing or fraze mowing should be considered. Develop a program that works for you, and stick to it. The results will be healthier soil and healthier turf.

References

- Carpenter, M. 2019. Fraze mowing for overseeding establishment and removal of perennial ryegrass (Lolium perenne L.). M.S. thesis, Mississippi State University, Starkville, Miss.

- Craft, J.M. 2016. Maintaining soil physical property integrity in turfgrass management systems. M.S. thesis, Mississippi State University, Starkville, Miss.

Barry Stewart is an associate professor in the Department of Plant and Soil Sciences at Mississippi State University in Starkville, Miss. He specializes in sports turf science.